Heat Treatment & Material Processing Lab

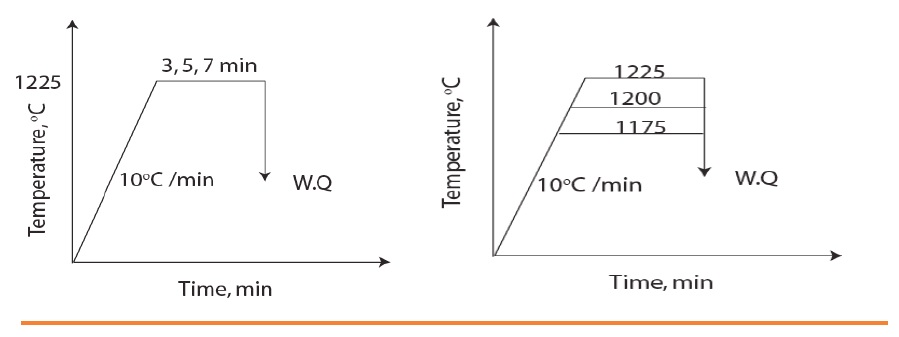

The graph shows a reheating cycle of the steel samples heated to 1175, 1200 and 1225˚C followed by soaking for certain periods of time and subsequently quenched in ice- water. The effect of reheating cycle was determined on the austenite grain size of the steel samples.

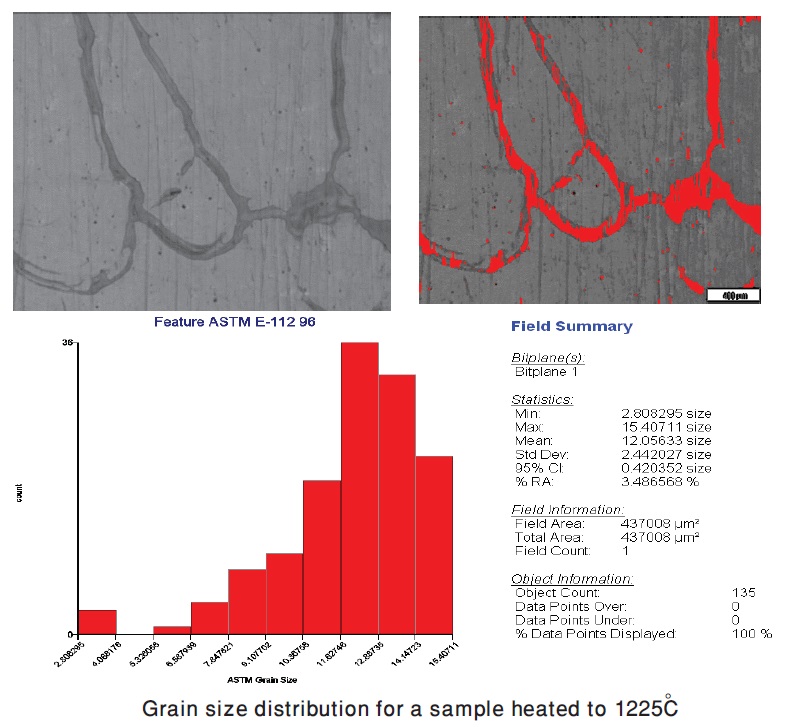

Image analyzer used to determine the grain size distribution in the heat treated sample at 1225 ˚C as per the ASTM standard.

Heat Treatment & Material Processing Lab is equipped with:

- Industrial Microwave

- Box furnace (1800C)

- 1600C three zones tube furnace for controlled atmosphere

- 1600C Box furnace for controlled atmosphere

- High Frequency Induction furnace

- Powder milling Disperser

- Powder mixer

- Mechanical attritor for cryomilling of powders

- Planetary ball mill

- Electrospinning apparatus for spinning of nano fibers

- Auto surb degasser unit for degassing of powders (400C)

- Vacuum drying oven (250C)

- Sensitive balance

- Bench type press with pressing dies

- Extruder for polymers and polymer based composites

- Rolling machine for metallic materials

- Extrusion machine for metallic materia

- Twin screw extruder